MINI CVT

Is your MINI not moving? Did the dealer tell you that you need a new CVT transmission? Many dealerships are asking over $8,000 to replace the CVT transmission on MINI Coopers. We can repair your vehicle’s transmission at half of the cost to replace it. We also can provide replacement repaired transmissions to qualified repair shops.

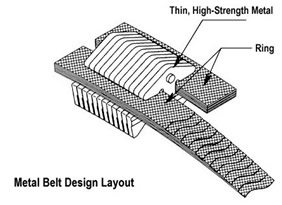

CVT Belt

The automatic transmission used on MINIs from 2003-2006 is known as a Constant Velocity Transmission or CVT. The fundamental difference between a CVT and a conventional automatic transmission is the CVT has no gear sets other than reverse. The vehicle is able to accelerate without changing gears due to a drive belt system that varies the ratio of the transmission. It is this drive belt that is the likely cause of your trouble.

The automatic transmission used on MINIs from 2003-2006 is known as a Constant Velocity Transmission or CVT. The fundamental difference between a CVT and a conventional automatic transmission is the CVT has no gear sets other than reverse. The vehicle is able to accelerate without changing gears due to a drive belt system that varies the ratio of the transmission. It is this drive belt that is the likely cause of your trouble.

Due to the unreasonable cost for a replacement transmission from the dealer, we have found a large demand for an alternative. These repaired transmissions are warranted for two years or 24,000 miles (whichever comes first). We have been providing MINI services and repair since 2005 and prior to opening were servicing MINIs at the dealer. We own and drive MINIs.

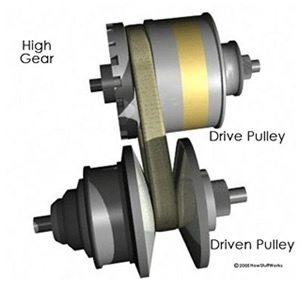

CVT Diagram

This page is dedicated to the understanding, repair and maintenance of the MINI Constant Velocity Transmission. There have been many MINI owners surprised when their CVT failed early (we have had failures from 55k to 110k miles) and to make matters worse, the MINI dealer then gave them an estimate of over $8,000 to replace it with a new one. We at Coast Motor Werk have spent many hours investigating the cause of these failures and devising solutions for our customers.

This page is dedicated to the understanding, repair and maintenance of the MINI Constant Velocity Transmission. There have been many MINI owners surprised when their CVT failed early (we have had failures from 55k to 110k miles) and to make matters worse, the MINI dealer then gave them an estimate of over $8,000 to replace it with a new one. We at Coast Motor Werk have spent many hours investigating the cause of these failures and devising solutions for our customers.

Before 60k CVT (auto transmission) woes.

Many Cooper owners with the CVT have been frustrated about various symptoms that feel wrong about the performance of their Cooper. These symptoms range from a jerking or lurching when accelerating to the engine RPMs going too high at freeway speeds or when decelerating. Often these symptoms are dismissed as “normal” at the dealer, or worse, the dealer advises a replacement transmission.

We have discovered the problem is related to software corruption caused by low voltage during cranking. In most cases a new battery, software and re-adapting the transmission cures the problem. This can save thousands of dollars over an unnecessary replacement transmission.

CVT Gears

First let’s talk about what a Constant Velocity Transmission is. A CVT is a transmission which can change steplessly through an infinite number of effective gear ratios between maximum and minimum values. This contrasts with other mechanical transmissions that only allow a few different distinct gear ratios to be selected.

First let’s talk about what a Constant Velocity Transmission is. A CVT is a transmission which can change steplessly through an infinite number of effective gear ratios between maximum and minimum values. This contrasts with other mechanical transmissions that only allow a few different distinct gear ratios to be selected.

The flexibility of a CVT allows the driving shaft to maintain a constant angular velocity over a range of output velocities. This can provide better fuel economy than other transmissions by enabling the engine to run at its most efficient revolutions per minute (RPM) for a range of vehicle speeds.

Alternatively, it can be used to maximize the performance of a vehicle by allowing the engine to turn at the RPM at which it produces peak power. This is typically higher than the RPM that achieves peak efficiency. The primary component of the transmission is the metal segmented belt that transmits the drive power to the output of the transmission and wheels.

Some Rendered CVT gears

Next let’s talk about the failures. Every CVT we have replaced failed in the same way. The drive belt bands broke causing the belt to come apart.

Next let’s talk about the failures. Every CVT we have replaced failed in the same way. The drive belt bands broke causing the belt to come apart.

Without the drive belt intact, the transmission is left completely disabled and the vehicle unable to move forward or back. The hundreds of small metal segments and metal bands that hold the belt together are now scattered throughout the transmission and have damaged the drive and reverse gears as well as the transmission case in nearly every transmission we inspected. Simply replacing the belt after this happens is not possible. At this point the whole transmission will require replacement.

Shredded belt

What can be done to prevent this from happening?

What can be done to prevent this from happening?

Due to the frequency of failures, we suggest replacing the drive belt at 60,000 miles. Although this is an expensive preventative measure (around $4,000), it pales in comparison to replacing the whole transmission. You can think of the repair as renewing your transmission for another 60,000 miles.

Although the jury is still out regarding the longevity of the rest of the transmission, due to the simple transmission design there are few other parts that can fail. How do you know if the belt is going to break?

Listen to your MINI. Noises ranging from rumbling at a stop in gear to knocking noises while moving from a stop are both signs the transmission belt is starting to separate. If this happens, stop immediately and have your MINI flat bedded to us.