Our goal is to fix and maintain your MINI quickly and accurately, without the costs and time associated with taking a vehicle to the dealer. We have invested in the factory service equipment to do so. We service MINIs only, and know them well. Give us a chance and I know you will be satisfied.

– Ron Inchausti, Owner

- Coding/Programming

- Diagnosis and repair

- Mecahnical repairs

- Electrical repairs

- Air conditioning repairs.

- Cooling system repairs

- Tires

- Alignment

- Maintenance

- Windshield repair/replacement

- Suspension

- Brakes

- Restoration

- Computer diagnostics

Here is a list that Coast Motor Werk has developed to address common MINI repair issues.

Help, I’m trapped!

Is your MINI’s window not going down?

Is your MINI’s window not going down?

Try this little trick. Open your door, now push the window down button while shutting the door firmly. If the window now operates, then you have a window motor that’s starting to fail.

This tip will get the window operating for a short time but plan to get it repaired soon. At Coast Motor Werk we can replace the motor with a new updated one the same day.

Call to schedule an appointment.

Not so cool.

A/C not working very well when stopped?

A/C not working very well when stopped?

The poorly designed two-speed radiator fan found on all 2001-2006 MINIs has a faulty low speed resistor.

When the resistor fails, so does the low speed function of the radiator fan. This is very important when using the air conditioner at idle or in traffic, as the fan cools the A/C condenser and keeps the A/C pressures in check.

Without the low speed fan, the condenser temperature as well as the pressure go up, causing the poor A/C cooling as well as putting undue strain on the compressor (potentially shortening its life). Replacing the fan assembly is the only repair offered by the dealer at a price of over $800. Worse yet, the new fan assembly has the same faulty low speed resistor.

At CMW we have found a better solution that will last and is much less expensive. By replacing the resistor with a new, better-designed one, we can save our customers hundreds or maybe thousands over the life of their MINI.

Stop that whining, please!

Power steering issue.

Power steering issue.

One common problem experienced in MINI cars has been premature failure of the electric power steering pumps, usually preceded by louder than usual whining.

Each time we have encountered this problem, the power steering fluid has appeared old with metallic debris in it. The fluid acts as the lubricant for the pump as well as for the rest of the hydraulic system and, unlike almost all BMWs, the system has no fluid cooler. To make matters worse, MINI has no recommended service interval for changing the power steering fluid.

CMW recommends the replacement of this fluid every 30,000 miles. We also use a special fully synthetic fluid to provide additional protection. This service costs less than $125 after tax and can be done while you wait.

My left thigh is huge. . .

My left thigh is huge. . .

Clutch too hard?

Premature clutch failure seems to be common on manual transmission MINIs. The cause for this is typically more of a throw-out bearing problem than a worn clutch disc.

The throw-out bearing is used to release the clutch disc from the flywheel. The bearing, if not operating correctly, damages the clutch cover and can even damage the transmission.

The first symptom of this problem is that the clutch pedal feels more difficult to push and seems more difficult to engage smoothly. Sometimes this problem is not noticed due to its slow progression, but knowing how the clutch should feel quickly identifies this problem.

The best approach is to have the vehicle inspected before the problem results in a breakdown…or worse, a visit to the orthopedic doctor.

There must be a bottle rolling around somewhere…

Clunking noise when driving.

Clunking noise when driving.

A problem we have found frequently in Coopers is a failed passenger side motor mount.

When functioning correctly, this hydraulically filled mount supports the motor while at the same time isolates it from the body. After a few years of service, however, the mount can rupture, causing the motor to sag slightly, resting on the inner metal frame of the mount rather than the cushion of hydraulic fluid. This causes a popping or cracking noise heard from the passenger side front of the car and usually evident when turning.

The mount has been updated, and the replacement should be expected to last longer than the original. This repair can be performed while you wait.

Soft brake pedal.

Nothing funny here.

Nothing funny here.

Frozen rear brake caliper slides, causing the brake pedal to feel soft or low, is a problem found on some MINIs. The repair involves removing, cleaning or replacing the slides and lubing with a water- and heat-resistant lubricant. This simple repair can prolong the life of the brakes as well as ensure the vehicle’s stability under braking.

Things that go bump or pop, squeak, tick in the night.

While squeaks, pops and rattles seem to appear from anywhere, we at Coast Motor Werk have found the source and the fix for most of them.

While squeaks, pops and rattles seem to appear from anywhere, we at Coast Motor Werk have found the source and the fix for most of them.

From trunk rear hatch rattling noises, sunroof and door noises to sounds coming from the dash, most repairs are simple and can help make your MINI motoring experience more pleasant.

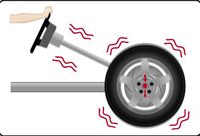

Steering wheel shimmy. Not the dance.

L ike BMWs, MINI vehicles use hydro-elastic bushings on the front suspension. The front suspensions of MINIs are very well designed and provide an incredible ability to control the vehicle in hard cornering and maneuvering situations while at the same time provide a comfortable ride. In most other vehicles, you get one or the other.

ike BMWs, MINI vehicles use hydro-elastic bushings on the front suspension. The front suspensions of MINIs are very well designed and provide an incredible ability to control the vehicle in hard cornering and maneuvering situations while at the same time provide a comfortable ride. In most other vehicles, you get one or the other.

BMW is able to accomplish this amazing combination mostly due to unique bushings installed in the front suspension of most BMWs and MINIs since 1995. The bushings absorb shock while minimizing deflection (movement) of the front control arms, which are responsible for keeping the front tires pointing in the same direction.

When the bushings are operating as designed, small pot holes, cracks and bumps are absorbed by a combination of hydraulic and elastic response. The metal-clad bushing is cast with a chamber of hydraulic fluid encased in rubber. The shock created when the front wheels hit something like a small pothole is transmitted via the fluid in all directions into the rubber and dispersed rather than simply compressing the rubber.

These bushings, much like your tires, can only last so long. Often the bushings will crack and rupture, allowing the hydraulic fluid to escape, and causing the steering to feel loose and sometimes shimmy while driving. Left unchecked, the front tires will wear prematurely and potentially lead to an unsafe vehicle.

It sounds like a creaky old door when I turn.

Strut mount failure.

An occasional problem found on MINIs is the failure of the front upper strut mounts. These mounts support the weight of the front of the MINI, and in most vehicles these mounts last a very long time. The symptom associated with the failure is a loud squeaking or rubbing noise when turning the steering wheel.

Fuel Injection Servicing

Fuel injection services can vary from shop to shop and from cleaner to cleaner. We have used quite a few and have found the BG system to be superior to most.

A service consists of running the vehicle until warm, then the vehicle’s fuel system is disabled. The pressurized BG fuel system cleaner is then connected to the vehicle and the engine is started. The engine actually runs on the cleaner, allowing it to work through the injectors, intake valves, combustion chambers and exhaust valves. Any unburned cleaner goes by the oxygen sensors and through the catalytic converter. We then disconnect the cleaner and reconnect the vehicle’s fuel system.

After restarting and road testing, the engine control system is reset to factory settings and any related service codes are deleted. We have tested the results and are honestly excited about the improvements that can be felt and seen. One example: We have had multiple vehicles that had failed smog inspections. We performed FI services and they passed. These vehicles would have otherwise needed new catalytic converters.

The wasted unburned cleaner can cause the catalytic converters to self-clean, and the cleaner helps reduce NOX emissions by cleaning the carbon from the combustion area. We have even had customers tell us their gas mileage increased after a service. We recommend the service every 30-60k.

Why original MINI brake parts?

Over the years we have tried many different variations of brake components on MINIs, and what we have learned is that the original brake rotors and linings perform better for street use than any other combination. The superior cold performance and lack of any noise or vibration makes them ideal for day-to-day driving.

The only drawback to original equipment is the dark grey brake dust caused by the high carbon linings. After-market linings can cure the dust problem but quite often create other issues. A shaking steering wheel as you slow from freeway speeds, and even when not braking, can often be cured with MINI brake discs/rotors.

As the non-original rotors heat cycle from driving they often become warped like an LP record. The MINI rotors are cast from a very soft and porous steel; they dissipate heat very uniformly, and when the factory linings are used, the pores at the surface of the rotors collect and hold carbon from the linings to help adhesion and minimize vibrations (noise).

Ever notice the way the rotors on your MINI rust in what seems like minutes after a car wash? Also, sometimes squeaks can be heard during a rainy day. This is a result of washing the carbon away. Our recommendation is original brakes on your MINI unless you intend to compete.

Remember to go easy on your new brakes for the first 200 miles. This will harden the lining materials and maximize the performance and longevity of the linings. Most brake jobs can be done the same day at Coast Motor Werk.

Bluetooth Integration

MINIs are driving machines, and anything that can prevent the driver from getting the full driving experience is undesirable. Phones can be one of those things. BMW started using hands free phones as far back as 1988. The problem was as the technology got better, the phones and their equipment quickly became outdated.

Bluetooth addresses this problem by eliminating clumsy wiring and allowing hands-free use of the phone, which can be replaced or updated whenever desired.

At CMW we can install Bluetooth integration into most models built from 1995 on. The convenience, safety, and – as of 07/01/08 – necessity of hands free phone is a nice upgrade.

What about the 15,000 mile oil change?

New MINIs with “full maintenance warranty” are limited to one oil service per year or when the service indicator tells you – this averages around 12-18k miles!

We believe the engine will fail prematurely due to the extended miles on the oil, and the long-term life of the engine might be extended if more frequent servicing is done. Unlike BMWs, MINI Coopers do not have an oil level sensor. It’s up to you or your mechanic. It’s very important to frequently inspect all fluids, belts, tires and hoses.

A visit to CMW every 6 months or 6,000-7,500 miles (5,000 on turbo charged models) to change the oil and filter, adjust tire pressures and perform a comprehensive inspection can save you money over the life of your MINI. It could also save you the inconvenience of a breakdown. Call us for an appointment.

Lifetime Transmission Fluid?

Since 1993, BMW has been sealing automatic transmissions and recommending “no servicing for the life of the transmission except CVT and M-cars.” Now it is true that transmission fluids do not live in the same harsh environment as the engine oil, so extended services are reasonable. However, it may be more prudent to replace the transmission fluid and filter every 75,000 miles to provide additional assurance that the MINI owner will not experience transmission problems. As with most repairs, CMW can perform the transmission service the same day.

Bumper-to-Bumper MINI Shop

Whether your check engine light comes on or you get a flat tire, we should be the one you call. Want your windows tinted? Got a dent? Remember, all we do is MINI and BMW, and if there is something you need or want for your MINI, we can provide it or advise you how or where to get the best solution.

Control Arm Bushings

The front suspensions of MINIs are very well designed and have an incredible ability to control the vehicle in hard cornering and maneuvering situations while at the same time provide a comfortable ride. In most other vehicles you get one or the other. MINI is able to accomplish this amazing combination mostly due to unique bushings installed in the front suspension. The bushings absorb shock while minimizing deflection (movement) of the front control arms responsible for keeping the front tires pointing in the same direction.

When the bushings are operating as designed, small pot holes, cracks and bumps are absorbed by a combination of hydraulic and elastic response. The metal clad bushing is cast with a chamber of hydraulic fluid encased in rubber. The shock created when the front wheels hit something like a small pot hole is transmitted via the fluid in all directions into the rubber and dispersed rather than simply compressing the rubber.

These bushings, much like your tires, can only last so long. Often the bushings will crack and rupture, allowing the hydraulic fluid to escape. When this happens, the bushing no longer holds the control arm firm and becomes very loose.

Common symptoms for worn out bushings include premature tire wear, tire noise, feathering of front tires, steering wheel shimmy at speeds between 30-50 mph, steering wheel shift when braking, and clunking or shifting from the front suspension.

Fortunately the bushings can be replaced, and in order to extend tire life should be replaced with every set of tires. Aftermarket or “heavy duty” bushings may last longer but can result in an undesirable ride. CMW uses the correct tools and techniques to replace these bushings at a fraction of the dealer price.

Brake Fluid

The brake system of your MINI uses a glycol-based hydraulic fluid. This fluid is “hygroscopic,” which means it will absorb moisture over time. Moisture lowers the boiling point of the fluid and causes internal corrosion in the brake system. That’s why the fluid should be replaced when brake repairs are done or every two years (regardless of mileage) as preventive maintenance. CMW uses a pressure bleeding system to ensure all of the fluid is replaced and no air is introduced.

Coolant

The coolant in your engine serves three important purposes. One is to protect your engine from damage from freezing. Here in sunny southern California we typically need not worry about freezing. The second is to keep the engine cool and is far more important – we all need to be cool, right? The third is just as important, and that is to protect the engine from corrosion.

One specific measure of protection is pH. If you have ever had a swimming pool then you know about pH. pH is a measure of the acidity or alkalinity of a solution. Liquids with a pH less than seven are considered acidic, while those with a pH greater than seven are considered basic (alkaline). A pH of 7.0 is neutral (like pure water).

The coolant pH in your MINI started at 8.5 and after a couple years will dip into the 6 range. At this point it’s doing more harm than good. Gaskets, hoses and seals are no longer being protected. They’re being eaten! It’s a slow process, but irreversible. It’s very important to replace the coolant with the correct type every three years.